EPISODE project

About EPISODE

EPISODE aims to develop sodium battery technology based on abundant available low-cost materials, with attractive energy density and power metrics. EPISODE’s battery will be durable non-toxic, non-critical, intrinsically safe and recyclable. Furthermore, the production processes for the anode, cathode, electrolyte solutions, binders and cell will be sustainable, energy-efficient and demonstrated at industrial mass manufacturing scale. The products developed in EPISODE create a stronger, more resilient and competitive energy storage systems. As such, “made-in-Europe” sodium modular battery systems with favourable CAPEX, OPEX and carbon footprint are produced as novel energy storage application technologies. The application of these modular batteries will be demonstrated for domestic installations and will be projected towards large utility installations of multiple MWh. Thus, EPISODE will establish an European-based, globally competitive battery supply- and value chain that supports economic prosperity and net-zero energy transition.

Objectives

The main mission of EPISODE is to launch a productive and cost-competitive European non-lithium battery value chain and to lay a fundament for industrial production of sodium (Na)-ion batteries (SIBs), ensuring Europe’s resource independence. EPISODE’s modular battery product is based on abundant and low-cost materials, having attractive energy density, cycling life and power metrics, as well recyclability potential. The project mission is divided into the following objectives:

Define a circular manufacturing concept for a demonstrable and highly sustainable EPISODE SIB cell chemistry with a feasible European-based supply chain.

Develop a SIB cell chemistry based on metal layered oxide cathode active material, hard carbon anode and electrolyte solution comprising of NaFSI salt.

Demonstrate and validate the performance of a 6.3 kWh SIB modular solution for home (residential) storage applications.

Advance the European battery manufacturing industry for SIBs via the construction of a strong business case around a 0.03 €/kWh/cycle storage cost target.

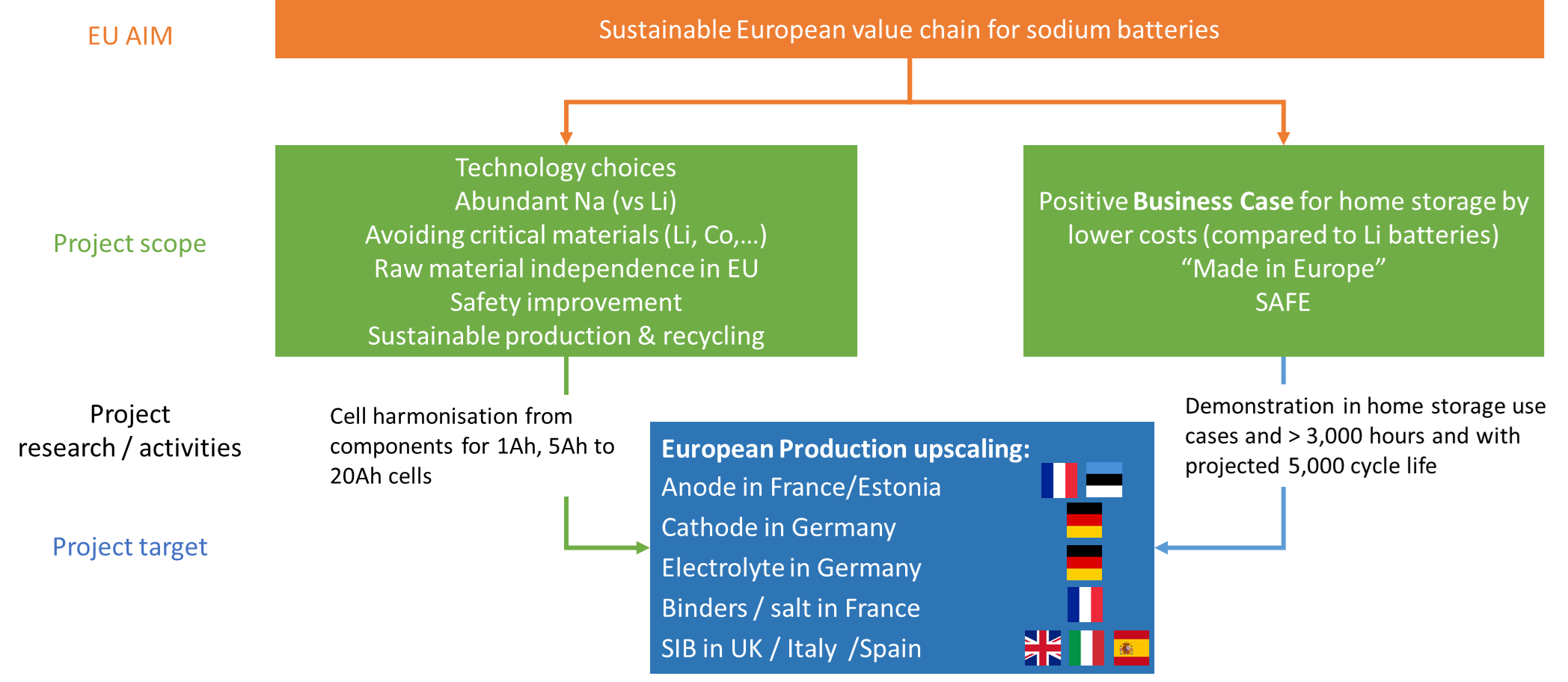

Concept

EPISODE aims establishing a sustainable European value chain for SIBs production. The focus is on upscaling the production of battery materials followed by the industrial manufacturing of key components such as anode, cathode, electrolyte, binder and salt, and separator. SIB cells will be firstly assembled at pilot scale. Thereafter, their production will be optimised and industrialised. The selection of SIB is driven by the abundance of sodium as a raw material in Europe, in contrast to lithium, along with the associated pricing advantages. Moreover, SIBs offer the flexibility of using aluminium current collectors for both cathode and anode electrodes, facilitating environmentally friendly manufacturing processes by utilising cobalt-free chemistries. These factors contribute to a strong business case for stationary storage applications, driven by lower costs compared to Lithium Ion batteries and reduced transport expenses due to locally sourced “made in Europe” components, cells and modules.

Approach

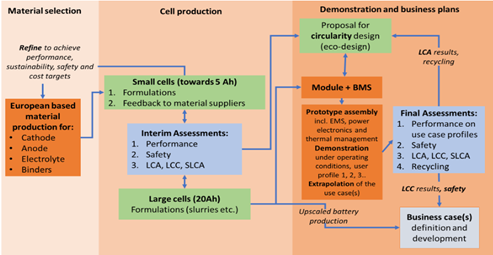

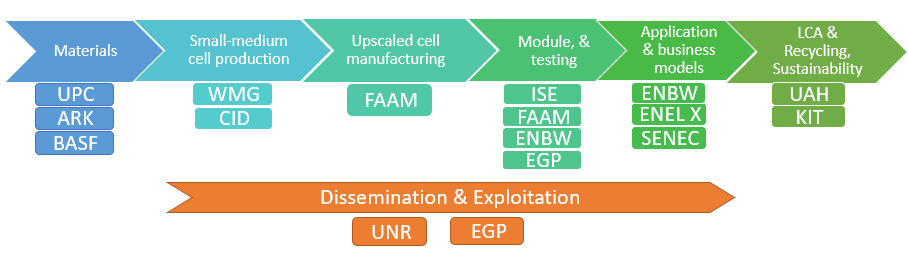

The figure shows the major steps of EPISODE: from setting up the requirements of material selection, cell production on small and larger scale, prototype demonstration to the application and the assessments towards a solid business case. At the beginning of the project, the choice of materials will be re-established during the requirements phase, allowing for small refinements (on cathode level especially) to allow the improvement of the formulation of slurries and the further cell harmonisation. The business case development allows the broader battery value supply chain to bloom after the project. There will also be an analysis towards extrapolation and demonstration into large-scale electricity storage and towards various mobile applications.

Step 1: Material selection

This step is about the choices of the materials and will be linked with the requirements set in in the early stage of the project by the end users. The material choices and optimisation carried out in this step will be closely accompanied by the sustainability assessment, which provides information about costs, potential environmental impacts and resource availability.

Step 2: Cell production

Pilot scale cell assembly lines will be used at WMG and CID to produce pouch cells (1-5 Ah) based on the (refined) cathode and anode materials. Building on the know-how gained by WMG and CID at the lower TRL level, FAAM will manufacture 20 Ah soft pouch cells (19 × 18 cm) to demonstrate production at an industrial scale using FAAM’s 300 MWh production facility.

Step 3: Demonstration and business plans

There will be interim assessments on performance (during the pilot-scale cell production in step 2), safety and on sustainability criteria. At project completion, the demonstration of cells in modules for residential storage application will be carried out together with the final safety and sustainability assessments. The performance assessment will also be performed considering the targeted KPIs: > 3,000 hours of operation and with proof of 2500 cycles without substantial degradation in capacity (> 80% of capacity retention) to obtain the projected cycle lifetime of > 5,000 full cycles. The final prototype will be tested under operating conditions. The test setups of Senec are such that the electricity supply is sub distributed as in a one-family home, such that the user behaviour can be depicted allowing for connection variants without modification of the test setup.

Picture below: Value chain

Results

EPISODE will deliver the following results:

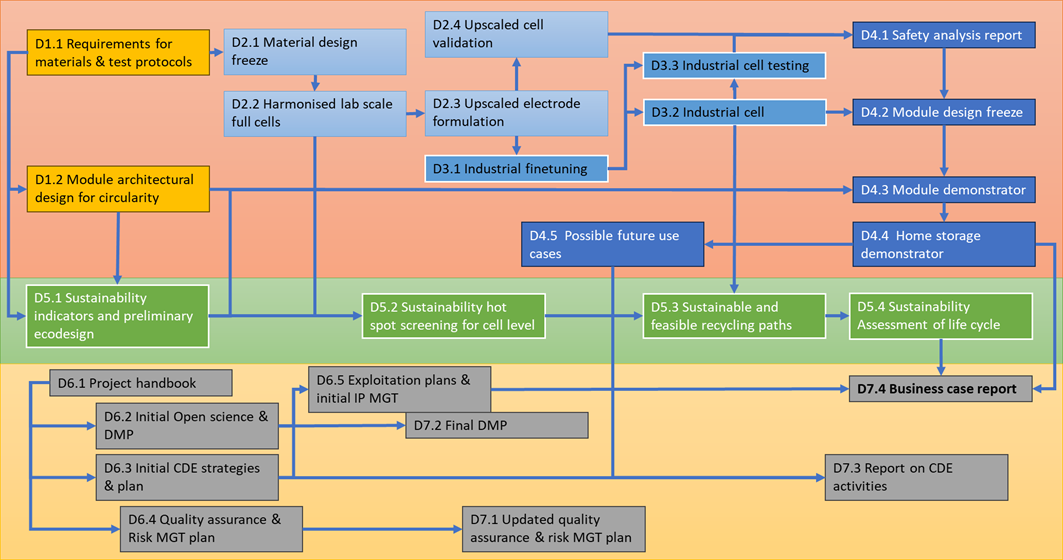

– Requirements for material precursors for EPISODE’s Na-ion batteries and module architectural eco-design for circularity. This is based on defining the performance, safety and sustainability requirements for the EPISODE module linked to the demonstration and its (future) applications.

– Small cells (1-5 Ah) based on refined materials (material design freeze) and upscale of their production to match requirements that are harmonised on full cell level as well as to validate electrode and cell manufacturing processes (10 L mixers, 5 Ah capacity).

– Demonstration of industrial production of Na-ion cells by building soft 20 Ah pouch cells finetuned from the small cell parameters. These cells should exhibit a capacity of 20 Ah and 2500 cycles with > 80% capacity retention at 1C rate, as considered by the industrial cell testing and cell ageing.

– Safety analysis for Na-ion cell and modules based on gas and energetic analyses, complemented by standard test for stationary storage application, i.e., passing the IEC 62619 test (as for LFP batteries) as input for policy feedback on regulations for Na-ion batteries.

– 6.3 kWh home storage demonstrator (small scale domestic application/back-up system) with test profiles in end-user conditions for > 3,000 hours based on modular and flexible frame system. The development of a cutting-edge Battery Management System will also be designed for stationary SIBs with real-time processing features and MQQT based data transfer.

– Report on possible future use cases considering upscaling scenarios that will include an overview of necessary steps to adapt the developed cells and modules technology to other use cases.

– Plan that identifies and ensures the best exploitation of the project results during and after the project.

– Assessments on sustainability and feasible recycling paths to ensure that the batteries are developed according to sustainability and circular economy principles, following an integrated life cycle driven approach under consideration of advanced economic, environmental, social and ethical metrics. The goal is to assure the use of abundant, non-toxic, inherently safe raw materials and minimum impact of possible value chain disruptions.

– A decision support tool to convey the complex and multidimensional outcomes from sustainability assessment and to identify trade-offs.

Facts and figures

Acronym: EPISODE

Duration: 42 months

Start date: 1 December 2024

EC funding: € 6,597,981.39

Publications

Coming soon.